The baffles have been the core of this project, both literally and figuratively. Developing a baffle that does not deform in heat, while being made in a heat-sensitive material has been a challenge.

The FTN.3 baffle (AKA the slanted K baffle) was found to be a very heat resistant design. In a traditional cone shape, the apex of the cone tends to deform when the material is heated and softened. The K baffle resists this, because the apex of the cone is tethered to the walls of the can. As the material is heated up and softened, it resists permanent deformation because it is tethered to the walls. Even when soft, PLA is very tear-resistant. This means that key to heat resistant polymer baffles is to design them so they retain their shape even in a softened state.

Adding a slant to the face distributes the load along multiple layer lines. Adding a clipped edge helps trick the expanding gas into the secondary/false chamber.

This type of baffle design works very well with slow moving gasses (rimfire, pistol calibers, subsonic 300blk).

However in fast moving gasses, K baffles do not work as well because the gas tends to "skip" or bypass the false chamber.

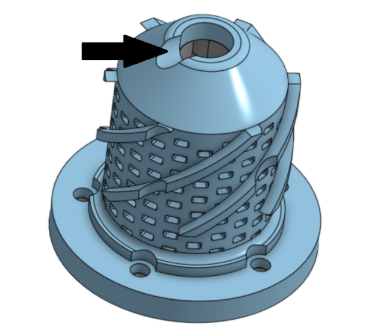

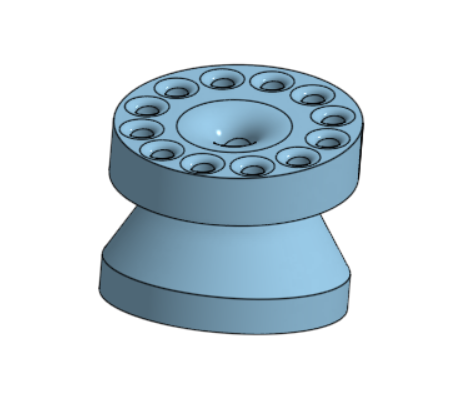

To address this, the FTN.4 baffle retains the apex-tethering features, but has many holes to allow the fast moving gas to pass through. Even though this creates a complex looking design, it is fundamentally just a cone (proven to work very well with rifle rounds), with suspension struts supporting the apex.

For the FTN.5 release, there were a few new baffles introduced. The proven FTN.3 slanted baffle was given ribbing to add to turbulence. K baffles are best for slow moving gasses like 9mm and 22lr, which are also the conditions that benefit from this kind of texturing. The benefit for rifle calibers would be much less compared to 22 or 9mm.

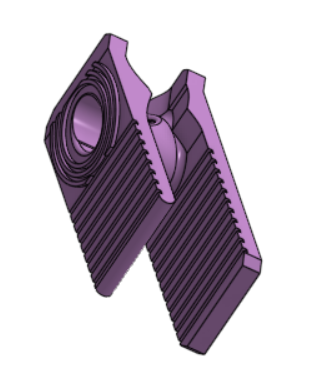

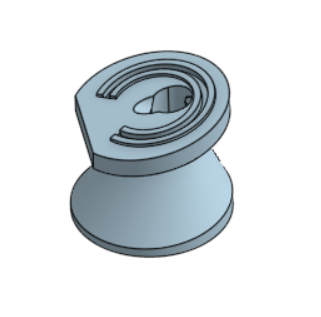

A modified slanted K baffle was made for the osprey and also the off-axis bore pistol cans. Functionally this is pretty similar to the original FTN.3 slanted K baffles.

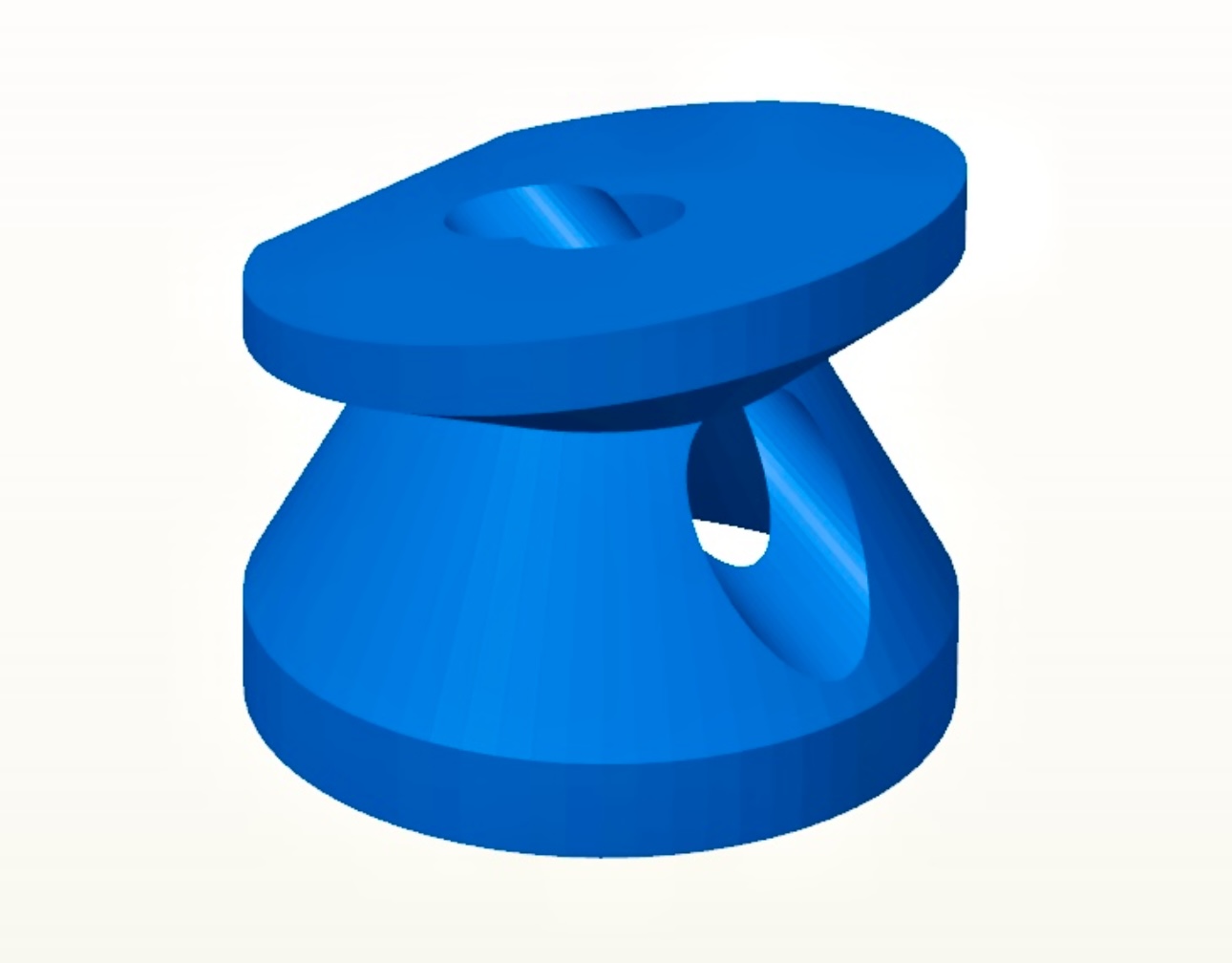

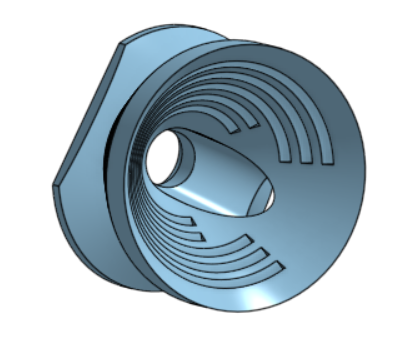

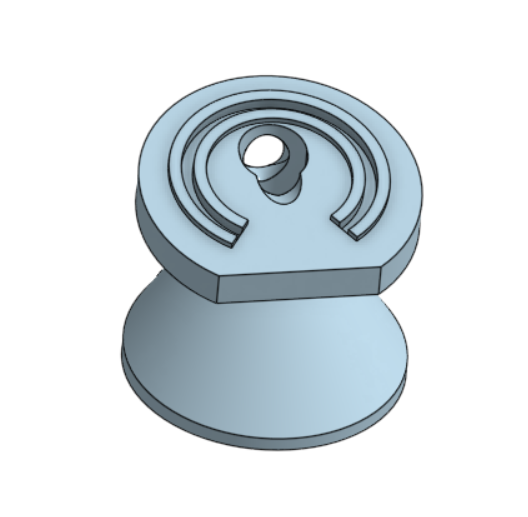

There is also a new tesla valve baffle. This seeks to replicate the tesla valve effect. It depends on laminar flow (as opposed to most baffles that work through turbulence). Gasses are directed around a center obstacle, and curved backwards towards the main path (the bore). Redirecting gasses to flow directly into the center path causes a significant amount of resistance to forward flow.

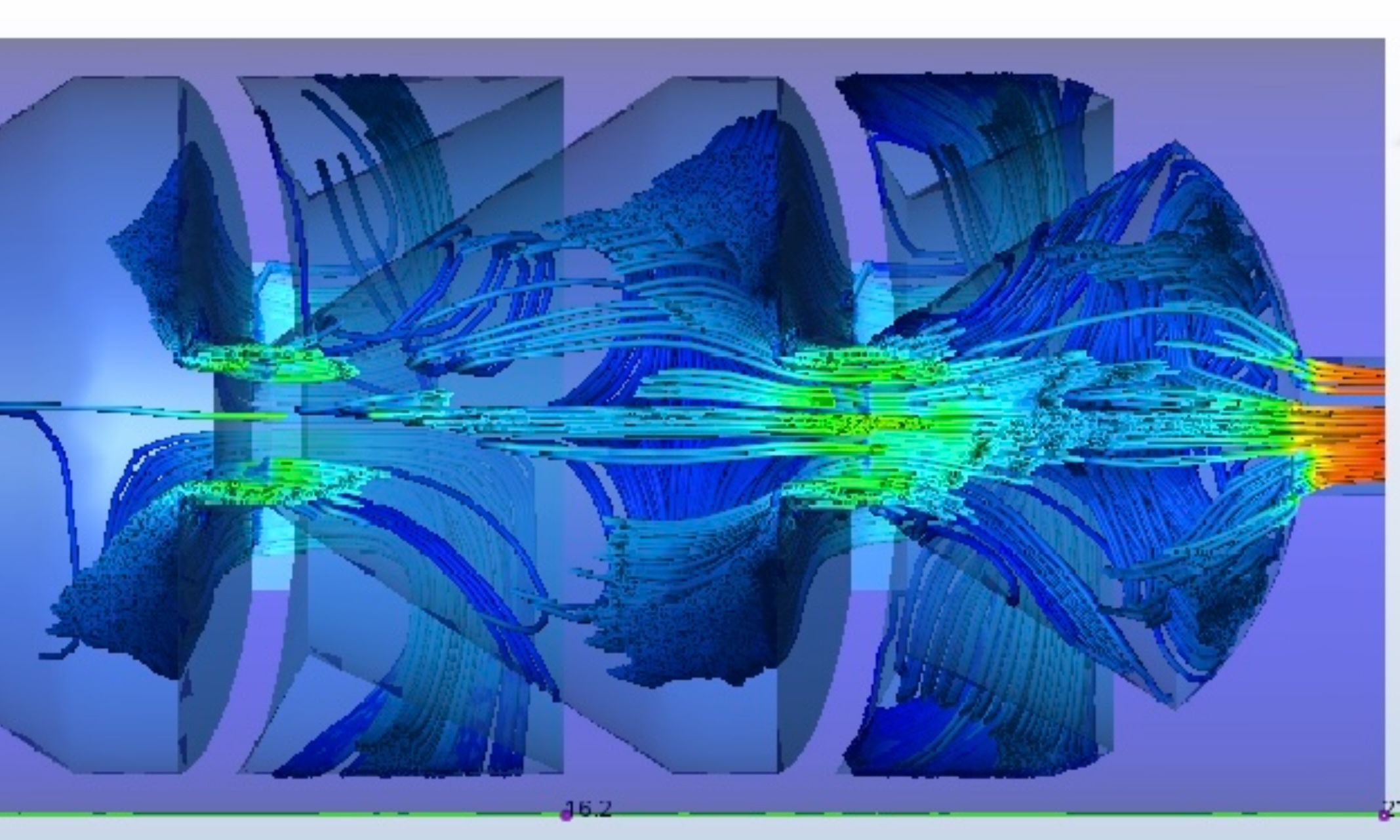

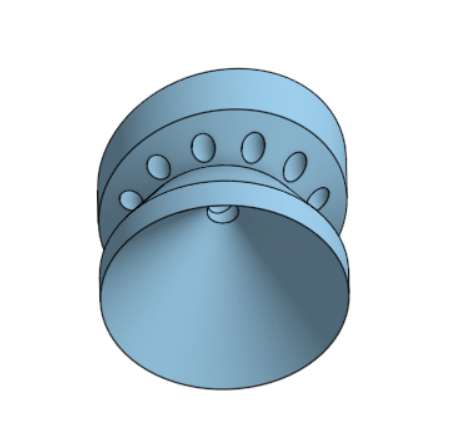

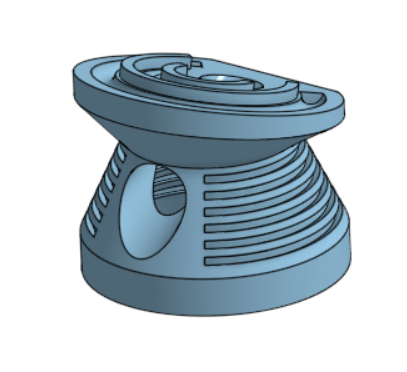

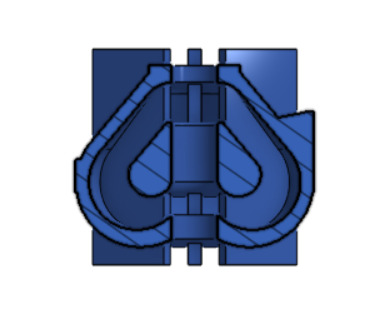

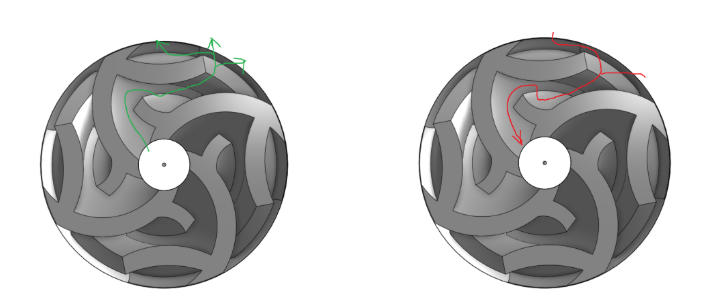

Finally, not a baffle per se, but I have a new Gas Diverter Core. This is used in the Maelstrom flow-through suppressor series. At first glance, this may look like a baffle stack but it does not function like a baffle stack. It preferentially diverts gas through a spiral path to the periphery where it can enter the outer flow-through chambers. Backward flow to the core is dissuaded due to the geometry.

!

!

Note in the cross section of the Gas Diverter Core above: The green pathway away from the center is the natural path of the gas. The gas does not naturally follow the red path from the periphery back to the core.

Critical to making the gas diverter core work effectively is the clip at the top of the printable core. Clips function by adding a second direction vector. Think of a stream of gas traveling down the center. Now imagine a second stream going through the clip. These two streams collide and the second stream disrupts the main stream and pushes the wavefront off the midline, where the gas diverter can take effect